Heat Pumps and Net Zero

Heat pumps have a key role to play in heat decarbonisation, but they are not a panacea, says Ryan Kirkwood, Baxi's Heat Pump Business Development Manager.

We are all aware of the need to achieve near-total heat decarbonisation in UK buildings if we are to meet the nation's legally binding target of net zero emissions by 2050. Added to which, price volatility in the energy market makes it more important than ever to ensure a heating solution that ticks all the right boxes, from reliability and high efficiency to environmental sustainability and lifetime affordability.

A combination of electrification and hydrogen-based solutions along with deployment of low carbon heat networks will be necessary to address the huge decarbonisation challenge. Energy efficiency will also be key, as the most cost-effective resource available to reduce heat demand and meet our energy needs.

Manufacturers of heating equipment are preparing for the energy transition with a mix of low carbon technologies and techniques, including heat pumps, for use now while innovating with solutions such as hydrogen boilers for the future of heat.

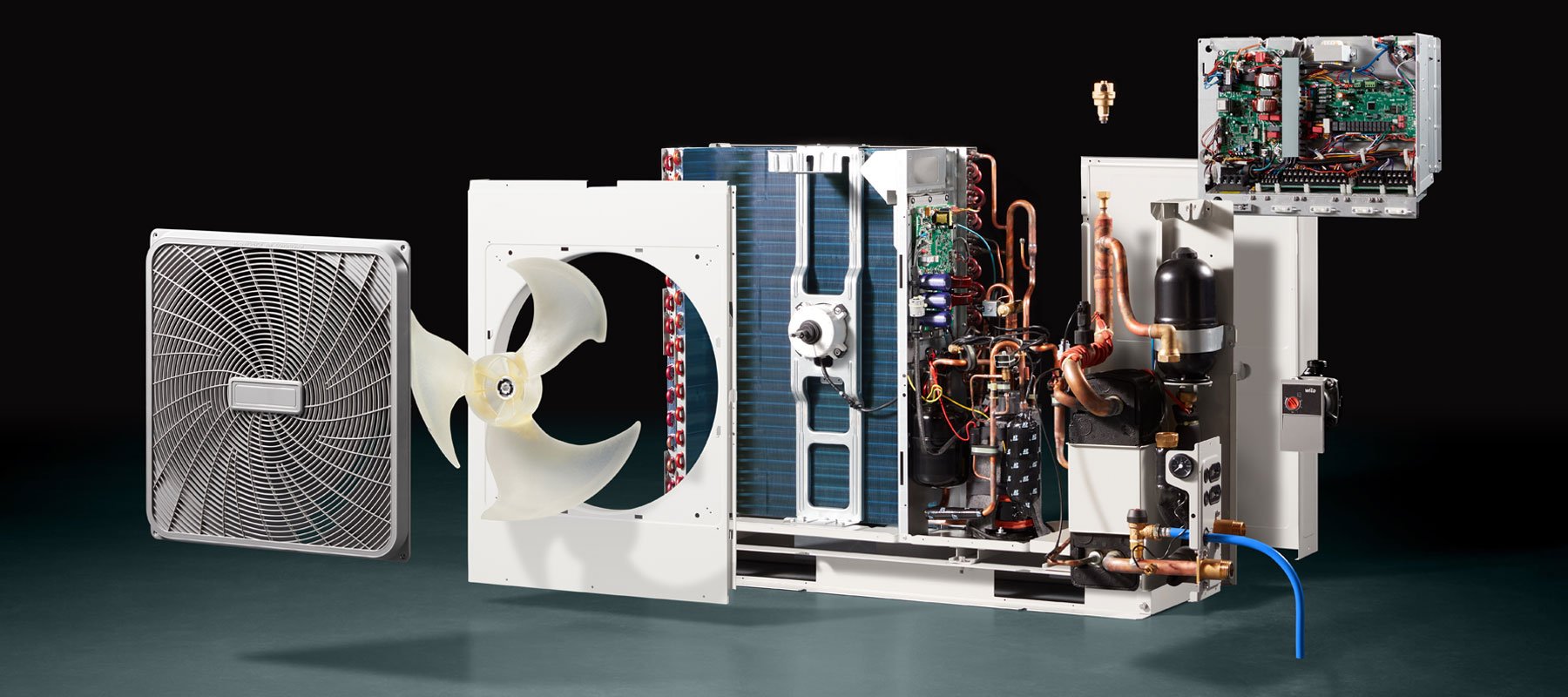

Clearly, heat pumps have a major role to play in the energy transition, particularly in buildings designed from the ground up to use low temperature heating effectively. We see Air Source Heat Pumps (ASHP) as the most popular and cost-effective choice of heat pump and are pleased to have added our new Remeha E-HP AW ASHP range to our expanding portfolio of sustainable heating and hot water solutions.

Powered by the UK's rapidly decarbonising electricity grid, this energy-efficient technology extracts renewable heat from the atmosphere and amplifies it using refrigerant compression. As such, it can provide a highly efficient, sustainable method of supplying low carbon heating or indirect hot water requirements for a range of commercial buildings.

Retrofit challenges

But here's the problem. Low carbon technologies perform best in well-insulated buildings and at low operating temperatures. Retrofitting air pumps in older, poorly insulated premises is a far more complex matter.

Limitations in these hard to heat buildings might include – but are not restricted to – physical space constraints, older heating and hot water systems that operate at higher temperatures, available electricity supply, poor insulation and limited budgets.

If we tailor the solution around the heat pump rather than the retrofit challenges in the building, the anticipated outcome will simply not be achieved. So how to overcome this?

Holistic approach

The majority of these older commercial buildings will likely need to be adapted first, through a series of steps, to make them ‘heat pump ready’. By taking a holistic approach, identifying the problems and the options, we can help balance client needs against outcomes and budget to achieve the best solution.

Even if full decarbonisation will not realistically happen overnight in many buildings, working together, we can help organisations plot a pathway to net zero and set them on their journey.

Good manufacturers will be able to provide valuable support. By asking the right questions, they will be able to gain a clear understanding of the business or organisation’s long-term goals and work alongside you to propose an achievable pathway to net zero.

How urgent is the need for refurbishment?

How much time is there to complete the work?

Is there sufficient electricity supply or will this require additional budget?

Is space limited? Is a pre-packaged solution required?

With early collaboration and knowledge pooling, we can work together to identify and deliver a solution based around each individual building and bespoke to its unique requirements.

Phased approach to decarbonisation

A further advantage of having phased refurbishment programme in place is that organisations can plan and budget ahead to achieve their immediate and long-term requirements and minimise disruption.

The starting point should be to reduce the energy consumption in the building and ensure that the fabric is suitable. One of the easiest ways to achieve this is to reduce heat loss and lower heat demand. Your preferred manufacturer will be able to assist with a free site visit to ‘triage’ the problems and assess the most appropriate options on a project-by-project basis.

Installing a more efficient system is a likely next step. Replacing any non-condensing heating plant with future-ready, low NOx condensing models can reduce energy usage and emissions by up to 20% while improving the reliability of the service.

Once the building and heating system have been brought up to code, a natural progression would be to integrate Air Source Heat Pumps and condensing boilers in a hybrid system.

Hybrid solutions

Hybrid heat pump systems are an effective means of overcoming typical project limitations in existing buildings and meeting heat demand more sustainably. In a well-designed system, they will reduce both greenhouse gas emissions and energy consumption, thereby helping energy managers balance environmental with economic goals.

The aim should be to maximise heat pump contribution performance where possible, while taking all project limitations into account. Care should be taken to design the hybrid heat pump system in such a way that it successfully maximises the efficiency of both technologies. Flow and return temperatures, ∆Ts, controls and, ultimately, the detailed hydronic design should be taken into careful consideration when blending the technologies. Expert manufacturers will be able to provide advice on these aspects to address and avoid any conflict.

Achieving net zero

Decarbonising heat is vital if we are to meet our net zero target – but in the UK’s many poorly insulated buildings it is no mean feat and can seem overwhelming.

Both hybrid heat pump systems and standalone, purpose designed ASHP systems offer the opportunity for important efficiency gains and emission reduction to drive heat decarbonisation in existing and new commercial buildings.

We look forward to supporting specifiers with our high performing products, technical, product and legislative knowledge, and solutions-focused approach so that working together, we can maximise heat pump performance and ensure optimal outcomes.

Heat Pumps

Remeha heat pumps are practical, low-carbon, low-NOx heating solutions for commercial and industrial buildings.

Related Articles

Energy Transition

Preparing existing non-domestic buildings for the energy transition

Energy Transition

Making buildings heat pump ready

Energy Transition

Multivalent approach to domestic hot water generation

Energy Transition

The Delta Difference

About Remeha

Our dedicated experts and comprehensive project approach support you from concept to commission to achieve your project goals.