A complete range of floor standing boilers designed for space heating and indirect hot water production. Available in a wide range of models providing flexibility for plant room design and ensuring maximum efficiency.

With their extremely compact design, the Remeha floor standing boilers can be installed in a wide variety of configurations on either new or refurbishment projects. Their compact designs and ability to be installed in line or back to back offers added flexibility in floor design. The floor standing range is also compatible with Combined Heat and Power (CHP) units to create a new low-carbon plant room.

Our Solutions

Floor Standing Boilers

Our Solutions

Floor Standing Boilers

Gas 120 Ace

The Gas 120 Ace floor standing boiler provides maximum energy efficiency while the Remeha weather compensator options ensure the boiler closely matches the system demand.

Floor Standing Boilers

Gas 210 Ace

A compact, lightweight structure makes the Gas 210 Ace floor standing boiler quick and easy to install.

Floor Standing Boilers

Gas 220 Ace

The Gas 220 Ace is a premium floor standing boiler that exceeds expectations in performance capability and design simplicity.

Floor Standing Boilers

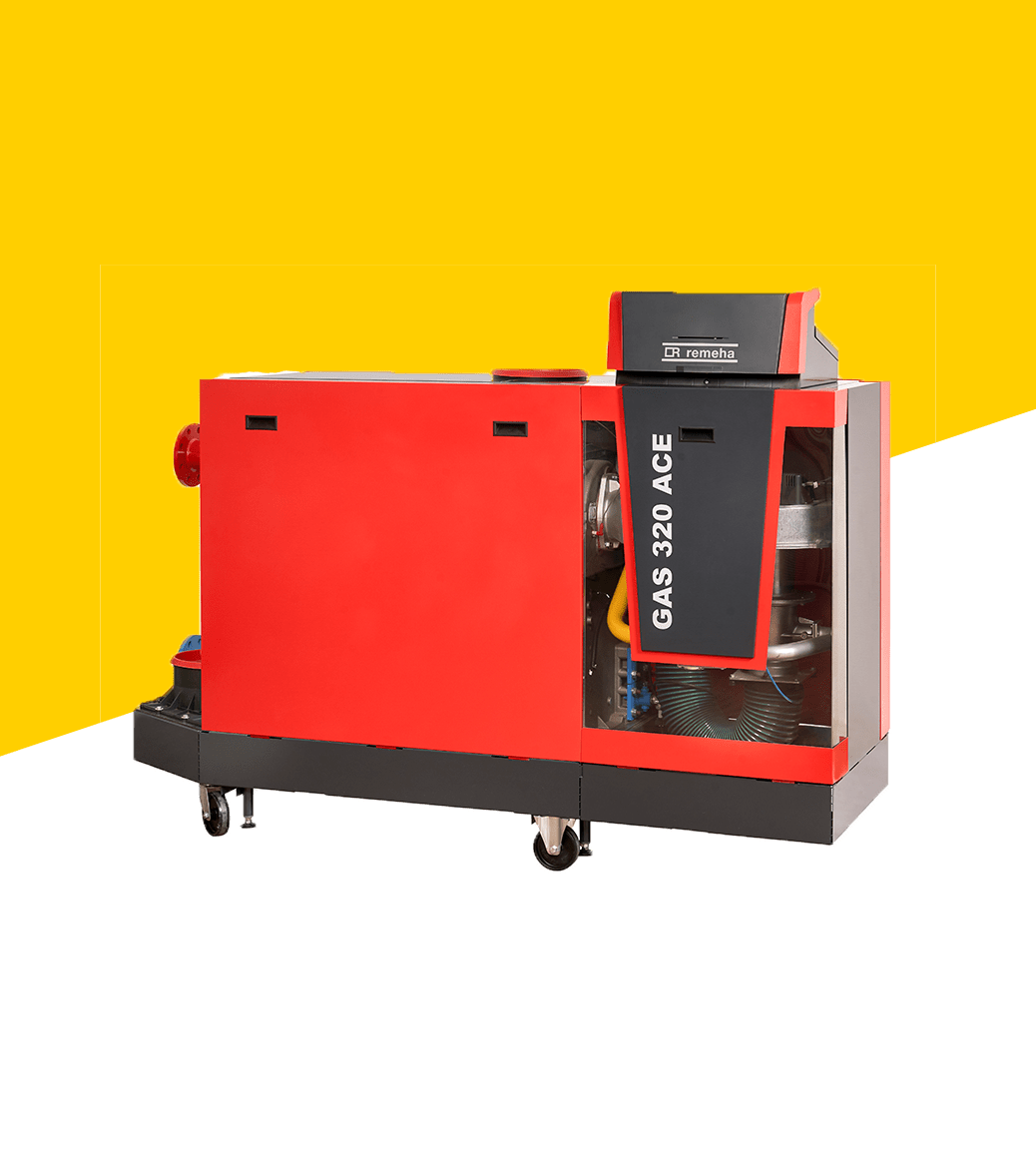

Gas 320 620 Ace

Engineered for reliable and efficient performance, the Gas 320/620 Ace floor standing boiler is designed with new and old building plant rooms in mind.

Our Solutions

Find out more about our energy efficient heating products.