Queen Elizabeth University Hospital

Installation: 3 x Remeha Gas 620 Ace boilers in packaged plant room

Baxi’s future-proof packaged plant room supports hospital’s drive for energy efficiency

Baxi Packaged Solutions has designed and built a unique packaged plant room that includes three Remeha Gas 620 Ace condensing boilers to meet the requirements for more energy-efficient heating, minimal disruption and future flexibility at Glasgow’s Queen Elizabeth University Hospital (QEUH).

The QEUH, which is operated by NHS Greater Glasgow and Clyde (NHSGGC), is built on the site of the former Southern General Hospital in Glasgow’s Govan district. While most of its facilities date back to its opening in 2015, some buildings, including the Maternity Unit, were retained from the previous hospital.

When the time came to replace the ageing boiler plant serving the 1970s facility, a series of factors increased the complexity of the refurbishment challenge.

Improving the efficiency of the existing heating system was the urgent requirement and one that could be achieved through the installation of more energy-efficient modern condensing boilers.

However, while this was an immediate concern, a master plan for the overall site, potentially including future connection to a district heating system, was already in development. Asbestos issues that could present a safety risk to the boiler replacement project and future maintenance work also needed consideration. Continuity of the heating service was a critical requirement for patient care, meaning that disruption had to be kept to an absolute minimum. Installing temporary plant to avoid shutdown of plant was not an option due to the size of the building.

To future proof the boiler replacement solution at the Maternity Unit and overcome all other project challenges, the NHS estates team decided to install the new boilers in a containerised plant room.

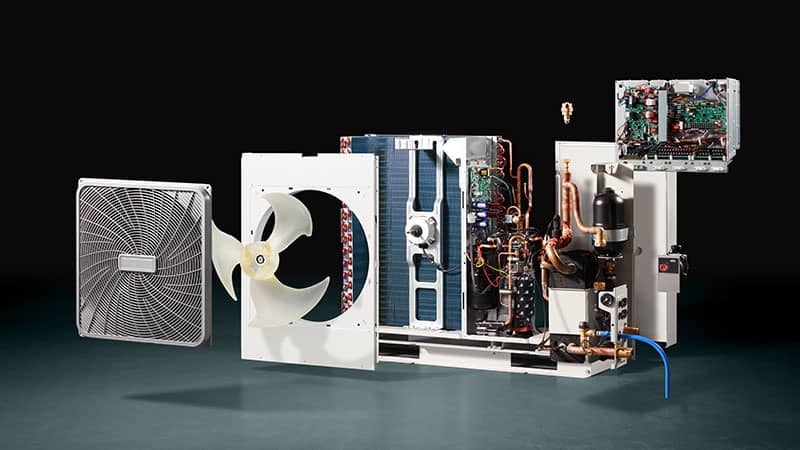

Baxi Packaged Solutions was selected to design and build the externally sited packaged plant room. This contains the three Remeha Gas 620 Ace boilers, with a total output of 3,600 kW to provide the required high output space heating, complete with all pipework, an air/dirt separator and a dosing pot, along with power and lighting via a small distribution board. The plant room is designed to connect to a new low loss header and plate heat exchangers in the main building and provides sufficient space to accommodate this equipment if required at a future date.

Project consultant Craig Gallacher at WGM Consulting Engineers said: “We approved the appointment of Baxi Packaged Solutions due to their experience and expertise as specialist providers of packaged plant solutions.

“In terms of the boilers,” he continued, “we specified the Remeha Gas 620 Ace boilers because of their reputation for quality, our own experience of using Remeha boilers over the years and the excellent support we receive from our Baxi technical sales manager. The positive feedback we received from the NHS GGC estates team on the higher output Remeha models and the ease of maintenance was a further determining factor. The boilers are also quiet in operation which is an important consideration when installing boilers in a containerised packaged plant solution.”

NHS GGC are pioneers in their use of packaged plant rooms to provide flexible solutions for improved energy efficiency across their estates and reduced carbon emissions. The estates team understands that refurbishing older buildings and their heating systems may need to happen in stages. This is reflected by the plans put into place for this particular project which will has been designed to deliver multiple benefits.

First, the container will last for 20 to 25 years, so there is the opportunity to use it for other sites, meaning that the intermediate solution for the Maternity Unit is not wasted. BPS has designed the container specifically to ensure flexibility for future use.

Second, the packaged plant room is a safe space for operatives, helping the NHS estates team ensure best practice compliance with all health and safety regulations.

Third, BPS’s offsite fabricated solution is factory-made, fully tested and quality-assured. Thanks to the use of specialist machinery, improved control procedures and comprehensive end-of-line testing, the highest build quality has been achieved with greater efficiency and with a lower carbon footprint.

Importantly, using this prefabricated solution has considerably reduced installation time at the Maternity Unit compared with traditional onsite methods, minimising onsite labour. By freeing up Soron, the project contractors, to move ahead with other work, it has effectively made it easier to meet the tight schedule.

Craig Gallacher added:

“We’re delighted with how the project has gone at the Maternity Unit as well as with our experience working with the Baxi team.

“The packaged plant room not only looks great, but it successfully meets the immediate and longer-term project requirements. The key drive behind this method was that of minimising disruption and enabling building operation at the Maternity Unit to keep running efficiently.

The NHS GGC estates team is equally pleased with the progress. Baxi’s complete solution exceeds expectations, with the Remeha boilers improving the efficiency of the heating system and the packaged solution creating a safe – and future-proofed – flexible space for the NHS operatives to work in. In short, it has ticked all the Board’s boxes.

They said: “It is essential that, when dealing with existing healthcare estates, we use pioneering techniques and out-of-the-box thinking to arrive at solutions which cater for a range of requirements. From patient care, safety and continuity of services, through to retrofitting new, sustainable plant into existing buildings and systems, the complexities can be overwhelming. This plantroom solution covers everything from the immediate needs of the building as well as wider Board views, giving us the flexibility to develop the existing estate in line with the overall NHS net zero values and targets.”

Baxi Packaged Solutions are specialists in prefabricated modular systems, from large exterior packaged plant rooms and energy centres to skid modules and utility cupboards. The team offer a complete service from concept to completion.

Engineered for reliable and efficient performance, the Remeha Gas 320/620 Ace is a compact high output boiler that is easy to install and easy to maintain. Its capacity to be installed side to side provides flexibility in plant room floor design and makes it perfect for use in packaged plant rooms. It also has an optional secondary return feature that makes it particularly suitable for use with heating technologies that use low grade heat, such as heat pumps or underfloor heating circuits. The Remeha Gas 320/620 Ace is fully backed by an industry-leading comprehensive 7-year warranty, when commissioned by Baxi’s commissioning engineers, and a 24/7 round-the-clock technical support helpline.

Remeha and Baxi Packaged Solutions are part of Baxi UK & Ireland.

Gas 620 Ace

For more information on the Remeha Gas 620 Ace boiler series. The Gas 320/620 Ace has the capacity to be installed side to side, which provides flexibility in floor design.

Baxi Packaged Solutions

Check out our comprehensive range of bespoke solutions, designed and built by our experienced engineers to meet your project’s unique specifications.

Related Articles

Energy Transition

Heat Pumps and Net Zero

Energy Transition

Preparing existing non-domestic buildings for the energy transition

Energy Transition

The Delta Difference

Energy Transition

Making Buildings Heat Pump Ready

About Remeha

Our dedicated experts and comprehensive project approach support you from concept to commission to achieve your project goals.