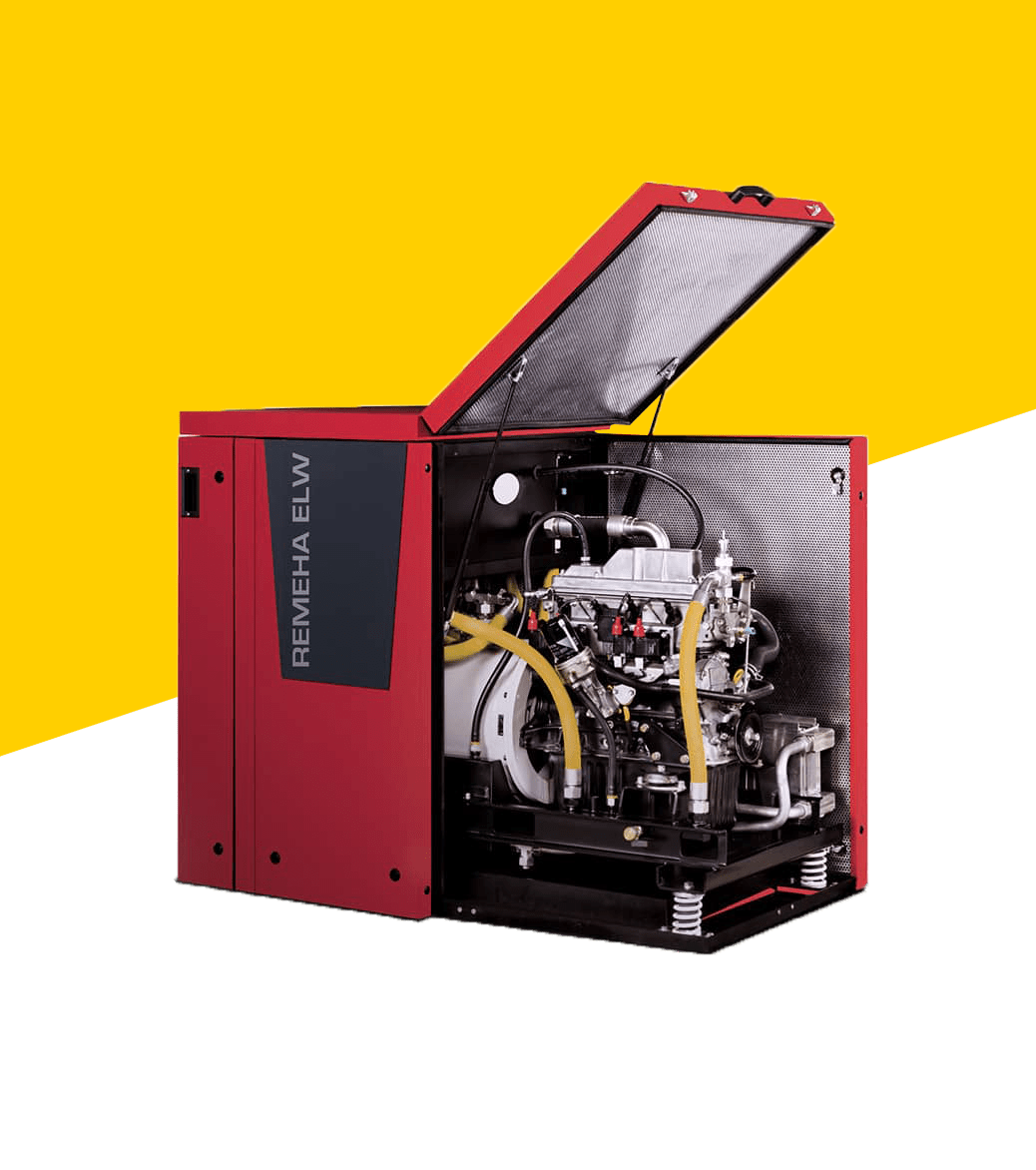

The Remeha R-Gen Combined Heat and Power (CHP) range is the sustainable solution to providing highly efficient heat and power for applications with consistent heating and electricity.

Converting gas into both electricity and heat in a single process at the point of use, the R-GEN NG operates at a higher level than traditional generation. It delivers a primary energy saving of up to 30% and up to 20% reduction in emissions.